Manufacture Better Flute Laminator,Cardboard Laminator, Die-cutting Machine

Focus on post-press equipment research and development, manufacture and sales for 20 years .

Focus on post-press equipment research and development, manufacture and sales for 20 years .

Tel: +86-315-5311888

Fax:+86-315-5311888

Sales Tel: +86-13623253438

E-mail:juxingjixie@sina.com

International Business Mail:

juxing@jiasun.com.cn

Machine · Specification

Specifications |

|

| Model | SZ1200BP |

| Max.Paper Size (mm) | 1200×780 |

| Min.Paper Size (mm) | 350×350 |

| Max.Cutting Size (mm) | 1180×760 |

| Weight (kg) | 15000 |

| Total Power (kw) | 23.5 |

| Speed(p/hr) | 0-6000 |

| Cardboard Sheet Thickness(g/m²) | 250-800① |

| Corrugated Sheet Thickness(mm) | 1-7 |

| Die-cutting Pressure(T) | 300 |

| Die-cutting Precision(mm) | ±0.5① |

| Dimension(mm) | 8000×4230×2250 |

| Power Supply | 3~380V(50Hz) |

| Model | SZ1300BP |

| Max.Paper Size (mm) | 1300×960 |

| Min.Paper Size (mm) | 400×410 |

| Max.Cutting Size (mm) | 1280×940 |

| Weight (kg) | 17000 |

| Total Power (kw) | 23.5 |

| Speed(p/hr) | 0-6000 |

| Cardboard Sheet Thickness(g/m²) | 250-800① |

| Corrugated Sheet Thickness(mm) | 1-7 |

| Die-cutting Pressure(T) | 300 |

| Die-cutting Precision度(mm) | ±0.5① |

| Dimension(mm) | 8750×4530×2245 |

| Power Supply | 3~380V(50Hz) |

| Model | SZ1500BP |

| Max.Paper Size (mm) | 1500×1100 |

| Min.Paper Size (mm) | 540×400 |

| Max.Cutting Size (mm) | 1480×1080 |

| Weight (kg) | 20100 |

| Total Power (kw) | 27.5 |

| Speed(p/hr) | 0-5000 |

| Cardboard Sheet Thickness(g/m²) | 250-800① |

| Corrugated Sheet Thickness(mm) | 1-7 |

| Die-cutting Pressure(T) | 300 |

| Die-cutting Precision(mm) | ±0.5① |

| Dimension(mm) | 9400×4795×2245 |

| Power Supply | 3~380V(50Hz) |

Parts · Introduction

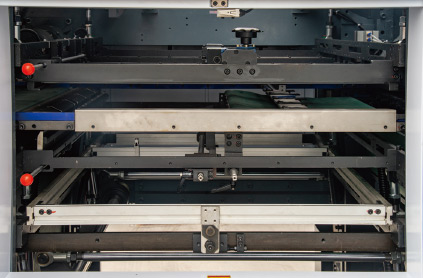

+Stripping part:

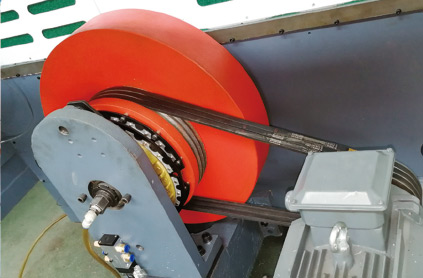

+The Large Torque Clutch:

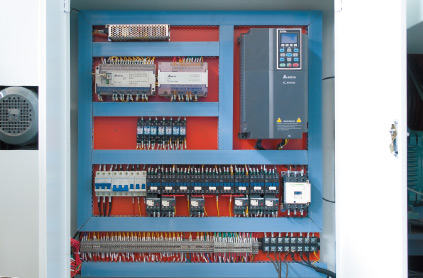

+Electric Unit:

+Full Stripping Unit(Optional)

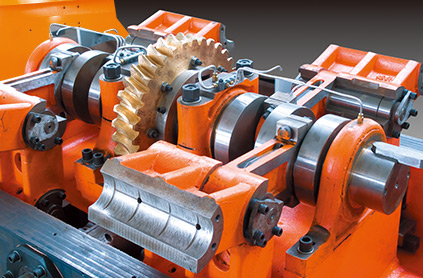

+Main Driver:

+Die-cutting unit: