Manufacture Better Flute Laminator,Cardboard Laminator, Die-cutting Machine

Focus on post-press equipment research and development, manufacture and sales for 20 years .

Focus on post-press equipment research and development, manufacture and sales for 20 years .

Tel: +86-315-5311888

Fax:+86-315-5311888

Sales Tel: +86-13623253438

E-mail:juxingjixie@sina.com

International Business Mail:

juxing@jiasun.com.cn

Machine · Specification

Laminator Specifications |

|

| Model | QTM1300 |

| Max. Sheet Size(mm) | 1300X1300 |

| Min. Sheet Size(mm) | 500X440 |

| Thickness of Face Paper(g/m²) | 120~450 |

| Thickness of Bottom Paper | ABCEF 3&5 Ply |

| Speed of Lamination(m/min) | 153 |

| Front lay Laminate Error (mm) | ±0.75 |

| Total Weight(kg) | 8700 |

| Total Length(mm) | 14180 |

| Operation Space(mm) | 3000x13500 |

| Total Power(kw) | 18.2 |

| Power Supply | 3~380V(50Hz) |

| Model | QTM1450 |

| Max. Sheet Size(mm) | 1450X1450 |

| Min. Sheet Size(mm) | 500X440 |

| Thickness of Face Paper(g/m²) | 120~450 |

| Thickness of Bottom Paper | ABCEF 3&5 Ply |

| Speed of Lamination(m/min) | 153 |

| Front lay Laminate Error (mm) | ±0.75 |

| Total Weight(kg) | 9500 |

| Total Length(mm) | 14180 |

| Operation Space(mm) | 3100x13500 |

| Total Power(kw) | 18.2 |

| Power Supply | 3~380V(50Hz) |

| Model | QTM1650 |

| Max. Sheet Size(mm) | 1650X1600 |

| Min. Sheet Size(mm) | 500X440 |

| Thickness of Face Paper(g/m²) | 120~450 |

| Thickness of Bottom Paper | ABCEF 3&5 Ply |

| Speed of Lamination(m/min) | 153 |

| Front lay Laminate Error (mm) | ±0.75 |

| Total Weight(kg) | 10500 |

| Total Length(mm) | 14300 |

| Operation Space(mm) | 3200x13500 |

| Total Power(kw) | 18.2 |

| Power Supply | 3~380V(50Hz) |

Flip-flop Machine Specifications |

|

| Model | FZ1300 |

| Max. Sheet size(mm) | 1300X1300 |

| Min. Sheet size(mm) | 500X440 |

| Min. Collecting thickness(mm) | 70 |

| Max. Collecting thickness(mm) | 180 |

| Max. Speed(p/hr) | 10000 |

| Pile height(mm) | 1300 |

| Machine weight (Kg) | 6000 |

| Power(Kw) | 8 |

| Dimension(mm) | 9350X3140X3300 |

| Model | FZ1450 |

| Max. Sheet size(mm) | 1450X1450 |

| Min. Sheet size(mm) | 500X440 |

| Min. Collecting thickness(mm) | 70 |

| Max. Collecting thickness(mm) | 180 |

| Max. Speed(p/hr) | 10000 |

| Pile height(mm) | 1300 |

| Machine weight (Kg) | 6900 |

| Power(Kw) | 8 |

| Dimension(mm) | 9500X3290X3300 |

| Model | FZ1650 |

| Max. Sheet size(mm) | 1650X1600 |

| Min. Sheet size(mm) | 500X440 |

| Min. Collecting thickness(mm) | 70 |

| Max. Collecting thickness(mm) | 180 |

| Max. Speed(p/hr) | 10000 |

| Pile height(mm) | 1300 |

| Machine weight (Kg) | 8000 |

| Power(Kw) | 9 |

| Dimension(mm) | 10500X3550X3300 |

| Model | FZ1950 |

| Max. Sheet size(mm) | 1950X1600 |

| Min. Sheet size(mm) | 800X600 |

| Min. Collecting thickness(mm) | 70 |

| Max. Collecting thickness(mm) | 180 |

| Max. Speed(p/hr) | 10000 |

| Pile height(mm) | 1300 |

| Machine weight (Kg) | 5500 |

| Power(Kw) | 9 |

| Dimension(mm) | 10500X3850X3300 |

Feature · Introduction

The machine is perfectly combined motion control system with servo system. With patent technology movement structure of our company, the machine idle speed can achieve to 15000 sheets per hour, and the effective speed can reach 12000 sheets per hour. In the case of face paper extruding condition, the operator can adjust the amount easily by inputting data to human-machine interface.

The machine is equipped with side puller lay to control the side precision of laminated sheet.

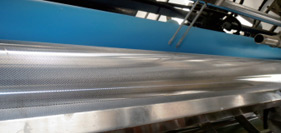

This machine is suitable for various type of corrugated and cardboard lamination.

The electrical components adopts imported parts with good stability.

Using frequency speed regulation system to realize the stepless speed change

The automatic glue system improves the degree of automation.

The machine adopts servo transmitting with the feature of quick response and accurate control. It can realize a non-stop running under a speed of 10000 sheets/h with 7mm thickness of 5 ply paper sheet. It can connect with all types of conveyor.

Unique turning structure of this machine can shorten the turning time, ensuring the stable running at high speed.

Aligning device together with the main and vice collecting system makes the machine run without stopping when pile is delivered out. It not only ensures a neat paper pile but also improves the production efficiency greatly.

Imported driving power, electric and pneumatic components provide a power guarantee for the machine.

Key parts processed by CNC lathe are assembled strictly under IS9000 standard allowing the machine run under low noise and stably.

Five patents are applied on this machine.

Part · Introduction

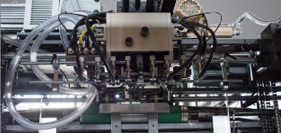

+High Speed Feeder

+Flip-flop Unit

+Front-lead feeding part

+Motion Control System

+Gluing Part

+Pile Delivery Unit