Manufacture Better Flute Laminator,Cardboard Laminator, Die-cutting Machine

Focus on post-press equipment research and development, manufacture and sales for 20 years .

Focus on post-press equipment research and development, manufacture and sales for 20 years .

Tel: +86-315-5311888

Fax:+86-315-5311888

Sales Tel: +86-13623253438

E-mail:juxingjixie@sina.com

International Business Mail:

juxing@jiasun.com.cn

Machine · Specification

Specifications |

|

| Model | 1307 |

| Max. Sheet Size(L×W) (mm) | 1270×720 |

| Min. Sheet Size(L×W) (mm) | 500×380 |

| Thickness of Face Paper (g/m²) | 100~800 |

| Thickness of Bottom Paper (g/m²) | 200~2000 |

| Speed of Laminating (p/min) | 150① |

| Front Lay Laminate Error (mm) | ±0.5② |

| Total Weight (kg) | 9000 |

| Total Length (mm) | 11830 |

| Operation Space (mm) | 3000×13500 |

| Total Power (kw) | 16.5 |

| Power Supply | 3~380V(50Hz) |

| Model | 1310 |

| Max. Sheet Size(L×W) (mm) | 1270×1000 |

| Min. Sheet Size(L×W) (mm) | 500X400 |

| Thickness of Face Paper (g/m²) | 100~800 |

| Thickness of Bottom Paper(g/m²) | 200~2000 |

| Speed of Laminating(p/min) | 120① |

| Front Lay Laminate Error (mm) | ±0.5② |

| Total Weight (kg) | 9000 |

| Total Length (mm) | 11830 |

| Operation Space (mm) | 3000×13500 |

| Total Power (kw) | 16.5 |

| Power Supply | 3~380V(50Hz) |

| Model | 1410 |

| Max. Sheet Size(L×W) (mm) | 1410×1410 |

| Min. Sheet Size(L×W) (mm) | 500×400 |

| Thickness of Face Paper (g/m²) | 100~800 |

| Thickness of Bottom Paper(g/m²) | 200~2000 |

| Speed of Laminating(p/min) | 120① |

| Front Lay Laminate Error (mm) | ±0.5② |

| Total Weight (kg) | 11000 |

| Total Length (mm) | 15130 |

| Operation Space(mm) | 3500×16200 |

| Total Power (kw) | 24.5 |

| Power Supply | 3~380V(50Hz) |

Feature · Introduction

BKJ1307/1310/1410 is specialized in the production of high-precision automatic cardboard lamination for thin paper, cardboard, gray cardboard, art paper, etc. to meet the demands of printed cardboard lamination. It has the features of high precision, non-deformation and flatness.

The main parts of the machine come from well-known brand either from abroad or domestic with long service life and good stability. Electrical components use international famous brands to ensure the reliability. The machine is equipped with five sucking and four forwarding feeder, differential speed registration system, synchronization lamination and other innovative design. It is made according to the European CE standards. The machine can also do automatic monitoring, automatic detection, fault display and alarming from feeding, registration, lamination to delivery.

Parts · Introduction

+Five sucking and four forwarding high precision feeder

+Electrical Part

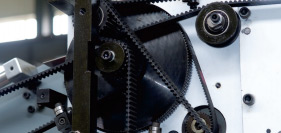

+Driving Part

+Chasing registration and side lay alignment structures

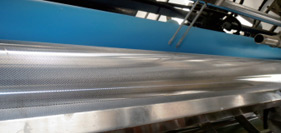

+Gluing Part