Manufacture Better Flute Laminator,Cardboard Laminator, Die-cutting Machine

Focus on post-press equipment research and development, manufacture and sales for 20 years .

Focus on post-press equipment research and development, manufacture and sales for 20 years .

Tel: +86-315-5311888

Fax:+86-315-5311888

Sales Tel: +86-13623253438

E-mail:juxingjixie@sina.com

International Business Mail:

juxing@jiasun.com.cn

Machine · Specification

Specifications |

|

| Model | QMY1200P |

| Max.Paper Size (mm) | 1200×780 |

| Min.Paper Size (mm) | 400×410 |

| Max.Cutting Size (mm) | 1180×760 |

| Weight (kg) | 19000 |

| Total Power(kw) | 32.5 |

| Speed (p/hr) | 0-5500 |

| Sheet Thickness(mm) | 1-7 |

| Die-cutting Pressure(T) | 300 |

| Die-cutting Precision (mm) | ±0.5 |

| Dimension(mm) | 8600×4230×2350 |

| Power Supply | 3~380V(50Hz) |

| Model | QMY1300P |

| Max.Paper Size (mm) | 1300×960 |

| Min.Paper Size (mm) | 400×410 |

| Max.Cutting Size (mm) | 1280×940 |

| Weight (kg) | 20000 |

| Total Power(kw) | 32.5 |

| Speed (p/hr) | 0-5500 |

| Sheet Thickness(mm) | 1-7 |

| Die-cutting Pressure(T) | 300 |

| Die-cutting Precision (mm) | ±0.5 |

| Dimension(mm) | 9100×4530×2345 |

| Power Supply | 3~380V(50Hz) |

| Model | QMY1500P |

| Max.Paper Size (mm) | 1500×1100 |

| Min.Paper Size (mm) | 500×410 |

| Max.Cutting Size (mm) | 1480×1080 |

| Weight (kg) | 22000 |

| Total Power(kw) | 36.5 |

| Speed (p/hr) | 0-4500 |

| Sheet Thickness(mm) | 1-7 |

| Die-cutting Pressure(T) | 300 |

| Die-cutting Precision (mm) | ±0.5 |

| Dimension(mm) | 9600×4795×2400 |

| Power Supply | 3~380V(50Hz) |

Feature · Introduction

Machine adopts the most advanced front-lead feeding structure which can effectively prevent and reduce damages to the surface of printed sheet.

The machine is a perfect combination of the motion control system with servo motor which ensures the operation more smoothly and reliable.

The machine is equipped with stripping part which can remove the waste on three edges and holes in the middle of the sheet after die-cutting (Stripping part is optional) .

Adopt imported electrical components – stable and reliable.

Using variable frequency speed regulation system to realize stepless speed change.

Part · Introduction

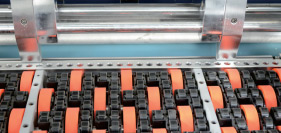

+Front-lead feeding part

+Stripping part

+The Large Torque Clutch

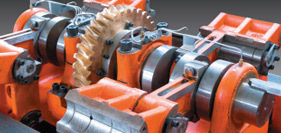

+Main Driver

+Die-cutting unit