Manufacture Better Flute Laminator,Cardboard Laminator, Die-cutting Machine

Focus on post-press equipment research and development, manufacture and sales for 20 years .

Focus on post-press equipment research and development, manufacture and sales for 20 years .

Tel: +86-315-5311888

Fax:+86-315-5311888

Sales Tel: +86-13623253438

E-mail:juxingjixie@sina.com

International Business Mail:

juxing@jiasun.com.cn

Machine · Specification

Specifications |

|

| Model | QMY1200P(SZ1200P) |

| Max.Paper Size(mm) | 1200×780 |

| Min.Paper Size (mm) | 350×350 |

| Max.Cutting Size (mm) | 1180×760 |

| Weight (kg) | 15500 |

| Total Power(kw) | 23.5 |

| Speed(p/hr) | 0-5000 |

| Cardboard Sheet Thickness(g/m²) | 250-800① |

| Corrugated Sheet Thickness (mm) | 1-7 |

| Die-cutting Pressure(T) | 300 |

| Die-cutting Precision(mm) | ±0.5① |

| Dimension (mm) | 8000×4230×2250 |

| Power Supply | 3~380V(50Hz) |

| Model | QMY1300P(SZ1300P) |

| Max.Paper Size(mm) | 1300×960 |

| Min.Paper Size (mm) | 400×410 |

| Max.Cutting Size (mm) | 1280×940 |

| Weight (kg) | 16500 |

| Total Power(kw) | 23.5 |

| Speed(p/hr) | 0-5500 |

| Cardboard Sheet Thickness(g/m²) | 250-800① |

| Corrugated Sheet Thickness (mm) | 1-7 |

| Die-cutting Pressure(T) | 300 |

| Die-cutting Precision(mm) | ±0.5① |

| Dimension (mm) | 8750×4530×2245 |

| Power Supply | 3~380V(50Hz) |

| Model | QMY1500P(SZ1500P) |

| Max.Paper Size(mm) | 1500×1100 |

| Min.Paper Size (mm) | 540×400 |

| Max.Cutting Size (mm) | 1480×1080 |

| Weight (kg) | 20000 |

| Total Power(kw) | 27.5 |

| Speed(p/hr) | 0-4500 |

| Cardboard Sheet Thickness(g/m²) | 250-800① |

| Corrugated Sheet Thickness (mm) | 1-7 |

| Die-cutting Pressure(T) | 300 |

| Die-cutting Precision(mm) | ±0.5① |

| Dimension (mm) | 9400×4795×2245 |

| Power Supply | 3~380V(50Hz) |

Feature · Introduction

Machine adopts independent motion control unit. The power transmission is done by servo motor and running is controlled by motion control system. It can achieve accurate cooperation between feeding unit and main machine and also self-movement model can be achieved.

Machine has manual and automatic models of motion state, when paper quality is poor, you can use manual model, easy to switch. When use manual model, space can be released and suitable for operation.

Machine feeding unit is independent systemed. It can be connected with other manufacture’s die-cutting machine.

The machine is equipped with stripping part which can remove the waste on three edges and holes in the middle of the sheet after die-cutting.

Part · Introduction

+Automatic State

+Manual State

+Stripping part

+The Large Torque Clutch

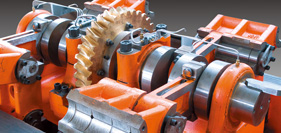

+Main Driver

+Full Stripping Unit(Optional)